Toggle clamps are all the rage nowadays. This is because they make it easier to work with workpieces as far as woodworking and metal work are concerned.

When you have toggle clamps, you don’t have to come up with creative ways to keep your workpieces from moving about as you try to cut them, attach them or drill through them. All you’ll have to do is purchase toggle clamps and use them to secure your workpieces, and they will do the excellent job of holding them together.

It sounds simple, doesn’t it?

This is until you realise that there is a lot more to buying toggle clamps than just deciding to buy one. There are certain things you must consider. Let us look at four critical factors you should consider when purchasing toggle clamps. These include:

Chapter 1: Clamping Force

image credit:engineeringclicks

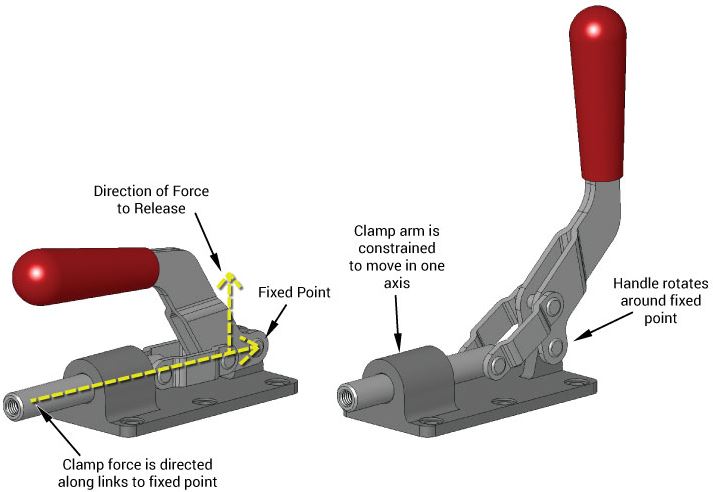

Clamping force is one measure that is used to rate toggle clamps. It refers to the amount of pressure that will be applied to your workpiece when your toggle clamp is locked against it.

But why do you need to consider the clamping force before buying toggle clamps?

Well, this is because they out want to steady your workpiece not damage it. If your workpieces delicate as an egg, you’ll need a little bit of pressure to secure it firmly. But if it is as strong as steel, you can use a lot more clamping force without damaging it. Clamping force is usually expressed in pounds. Thus, you should make it a point to check the toggle clamps clamping force in the manufacturer’s catalogue.

It would also be essential to note that the intensity of the force can be affected in things such as the position of the clamping bolt and the force applied to a handle. It may also be affected by the material of the workpiece. But as a rule of thumb, use smaller clamps for light-duty applications and larger ones for heavy-duty applications. In other words, don’t use a spade to do the work a spoon could easily do.

Now let’s look at something else you should consider.

Chapter 2: Holding Capacity

The holding capacity refers to the maximum external force the toggle clamp can resist when it is in its locked position without getting damaged or deformed. In simpler terms, the external force represents your workpiece. When your workpiece is placed into position, it should be able to fit between your workbench and the toggle plate.

If your workpiece is too ‘fat’ or large, it will end up deforming your clamp. Thus, it is essential to find out the toggle clamp dimensions. The dimensions will let you know the size of workpiece you can fit between your workbench toggle clamp plate. You can easily adjust the lever to secure ‘thinner’ workpieces. You can also use several toggle clamps to make your workpiece more secure. The important thing is to ensure that it fits well.

It is important to note that you can’t always judge the holding capacity based on the size of the toggle clamps. You have to check the height of the clamp to have an idea of what it is capable of holding.

Chapter 3: Design and Clamping Direction

There is one important thing you need to keep in mind as you buy toggle clamps. Toggle clamps come in different sizes and designs. It’s not enough to determine the clamping force and holding a capacity of clamps, but you also need to determine which design you’ll go for depending on your needs. As such, you can choose:

1: Horizontal toggle clamps

Horizontal toggle clamps are a common sight in workshops. They are often used to secure small workpieces. Horizontal toggle clamps can be identified by the position of their handles. Their handles are usually in a semi-vertical position before they are locked into place. Once they are in place, they are in the horizontal position.

Horizontal toggle clamps are usually mounted on a workbench. They work in conjunction with the workbench such that you place your workpiece between the workbench and clamping plate. Their hand grips come with a cushioned rib that makes it more comfortable to use. Horizontal clamps are best mounted towards the edges of your workbench. This way, the handle won’t be in the way as you work.

You can use such clamps to hold pieces of wood to your workbench as you complete tasks such as chiselling or painting. You can also use them to hold metals such as copper, iron or aluminium as you carry out applications such as welding or fabrication.

Horizontal toggle clamps tend to have a low profile. This just means that they are suitable for heights restricted applications. If you’re working with workpieces that are ‘short’, you will do well by using horizontal toggle clamp. Compared to other clamps, they come with varied holding capacities. You can measure its capacity by determining the distance between the workbench and the clamping plate when the plate is at the highest position. This will help you determine the size of work that the clamp will be able to hold.

At Rocheclamp, you can find horizontal toggle clamps with solid or ‘U’ shaped hold-down bars. These clamps come with various mounting options to suit your needs. You can choose standard or heavy duty toggle clamps. Or, you can decide to have toggle clamps customized for you.

2: Vertical toggle clamps

Vertical toggle clamps can be identified by the vertical position of their handles when they are in the locked position. To secure an object, you have to pull the handle away and then place the object under the securing bar. Once done, the handle will move into vertical alignment as pressure is applied. This is why such clamps are often known as vertical handle toggle clamps.

As with horizontal toggle clamps, vertical toggle clamps can be customized to meet your needs. You can choose solid or U-shaped clamps. These type of clamps come in handy when you want to secure objects around machinery. For example, you can use them to secure objects before cutting them with a jigsaw. Since the handle is at a 90-degree angle, it won’t interfere much with your movement. You can mount the clamps right in the middle of your workbench if you choose.

Vertical toggle clamps can be used together with horizontal toggle clamps. This is especially so if you intend to secure a large workpiece. Remember, the idea is to prevent the workpiece from moving as you work on it. Applications such as filling and sawing tend to cause workpieces to move, and this can mess up your work. It is thus prudent to use all means to secure such pieces.

One advantage of vertical toggle clamps is that they can withstand quite a bit of pressure. At Rocheclamp, you can find clamps with a holding capacity of 22,00kN. Thus, if you intend to do quite a bit of work on materials of various sizes, you should think about getting a vertical toggle clamp.

3: Push Pull toggle clamps

These types of clamps are also known as straight-line action toggle clamps. This is because their handles move the securing bars into straight lines. When you engage the handle of a push-pull toggle clamp, its securing arm tends to push into the object. It then locks and holds the object in place.

Push-pull toggle clamps have one special ability. They can be locked in two positions. This is what enables them to ‘push’ into the object or ‘pull: the object. It also helps that their handle is easy to operate.

You can find the push-pull toggle clamps with a holding capacity between 400N-70,0kN. This is a wide range of load rating, and it means you can use such clamps to secure various types of objects. However, these types of clamps are best suited for holding two objects together. If you have two pieces of wood that you want to glue together, for example, you can use a push-pull toggle clamp.

Remember, it takes a while for the glue to set. Instead of piling several books on top of your workpieces, you should use toggle clamps. However, you’ll need to be careful to clamp appropriately. As has already been stated, the clamp will apply some force to your workpieces. You don’t want to waste time clamping something that is out of place. This will only give you extra work instead of making your job easier.

4: Latch type toggle clamps

Latch type toggle clamps are the type of clamps you need when you want to pull two sides together. They can also be used to pull objects at 90 degrees. Their handle is aligned with the opposing latch. Thus, it tends to get pulled back down into a locking position.

It’s little wonder then that latch type toggle clamps, also known as pull-action latch clamps or latch hook toggle clamps, are used for closing objects. You can find them on doors, hatches, quick release covers or mould cabinet lids. They often have holding capacities up to 33,4kN. Thus, they perform really when even when applied to more massive objects. But as always, you need to check the clamping capacity to find the right latch type toggle clamps to use on various applications.

You can get J-hook toggle clamps, U-hook toggle clamps or Fixed latch type toggle clamps. Applications that have a height restriction will also benefit from latch type toggle clamps. This is because such clamps have a low profile. They can fit where it would be difficult for other clamps to fit.

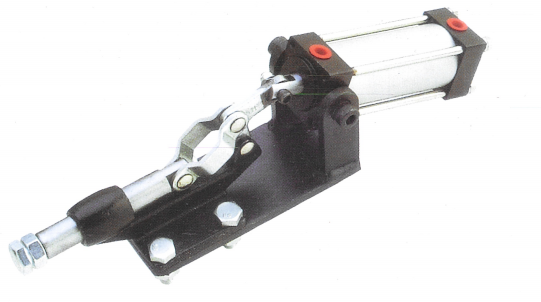

5: Pneumatic toggle clamps

Pneumatic toggle clamps work similarly to straight-line or manual hold-down clamps. The main difference is that these types of toggle clamps are operated pneumatically. As such, just like tools such as stapling guns and riveting guns, pneumatic toggle clamps are powered by compressed air.

This means that you won’t have to spend your time and energy trying to get the right clamping force for your workpieces. The air-actuated cylinders that are part of the clamp are the ones that will operate the clamping actions.

If you intend to perform repetitive, quick clamping operations, you really should think of getting pneumatic toggle clamps. This is especially so if you are doing short run jobs. Such clamps usually have temporary fixtures, and as such, you can quickly fix them and remove them once the job is done.

But be sure to check things like maximum cylinder air pressure, holding force and how wide the arms open before you buy pneumatic toggle clamps. Once you decide on the type of toggle clamps to get, you need to ensure you get the right toggle clamps material.

Chapter 4: Toggle clamps material

Another thing you should consider when buying toggle clamps is the material. You want a tool that will serve you well for a long time without the need for constant repairs. This is especially so if you intend to use it frequently. A beautiful clamp that breaks after one or two uses is not suitable for you.

So, which materials should you use?

Well, you should go for steel plated zinc or stainless steel. Stainless steel has a variety of properties that make it quite handy when making toggle clamps. These properties include elasticity, hardness and flexibility. Steel is also resistant to corrosion, and it also offers resistance to heavy wear from things such as impact, abrasion and friction. It also helps that the metal is easy to clean.

Take Home

Take your time to view the wide variety of toggle clamps Rocheclamp Company has to offer and determine which toggle clamp is best-suited for your clamping needs. There are a wide range of standard, heavy duty and precision toggle clamps you can choose.

If you don’t find one that you fits best to your nature of work, you can have one customised to your liking! We are a versatile company ready to serve you right.